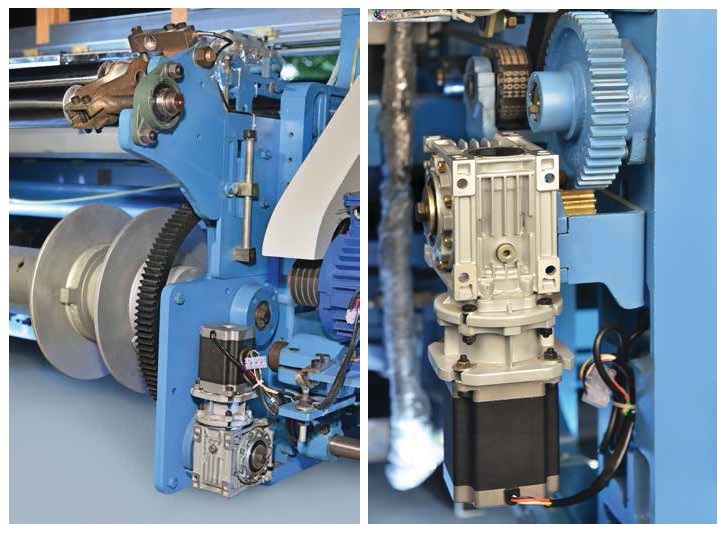

CONTROLLED & EFFECTIVE ELECTRONIC LET-OFF MECHANISM

-

Mounting mechanism of Whip Roller and Load-cell are specifically designed to get proper response of Warp Sheet Tension.

-

Continuous unwinding of Beam.

-

Keep identified Warp Sheet / Beam Tension and record it for the future reference.

-

Almost Constant Tension on Warp Sheet right from full to empty Beam.

-

Weaving of Even Fabric from first meter to last meter.

-

Lower & Upper Warp Sheet Tension’s safety feature reduces multiple warp breakages.

-

Few number of Parts thus less Maintenance.

VERSATILE ELECTRONIC TAKE UP MOTION GENERATES NUMBER OF POSSIBILITIES

-

Wants to change PPI? it is a matter of just pressing a finger.

-

Continuous movement resulting into Uniformity in woven Fabric.

-

5 Variable Densities unfolds vide scope of Value Addition Weaving Design.

-

Fringing option adds one more feather in the Woven Fabric.

-

Cramming of Wefts makes remarkable difference in the Fabric Design.

-

Extremely Less Parts thus less Maintenance.

USER FRIENDLY & STURDY AUTOMATION

-

Indigenously Developed Automation.

-

Noticeably reduction in no. of parts in the machine due to Automation.

-

Quick change of Parameters certainly saving time.

EASY CORRECTIONS OF LET-OFF & TAKE UP WITH MORE OPTIONS

To Tackle the Starting Mark Damage, below mentioned options are readily available:

-

Forward Kick of Let-off

-

Reverse Kick of Let-off

-

Forward Kick of Take Up

-

Reverse Kick of Take Up

-

Let-off “ON” Delay

-

Let-off “OFF” Delay

-

Take Up “ON” Delay

-

Take Up “OFF” Delay