Weaving is a process of making fabric with two separate sets of yarns called the Warp and the Weft. The Warp yarns in the form of sheet (called warp sheet) are wrapped on the beam and runs the length of the fabric. The Weft yarn is entirely separate yarn than the Warp yarns and it is laid between two layers / sheets of the Warp yarns (called Shed) across the width of the fabric. A new shed is then formed in accordance with the desired weave structure, with some or all of the ends in each sheet moving over to the position previously occupied by the other sheet. In this way the Weft is gripped between two layers of the Warps. Here one Warp yarn is called an End and one Weft yarn is called a Pick.

There was a significant development in 1733 when John Kay (Born in Lancashire, England) developed and patented the “Flying Shuttle” with metal capped ends, wheels and a pirn of weft thread for the hand loom.

Then Edmund Cartwright (Born in Nottinghamshire, England) designed his first power loom in 1784 and patented it in 1785, but it proved to be valueless. In 1789, he patented another loom which served as a model for later inventors to work upon.

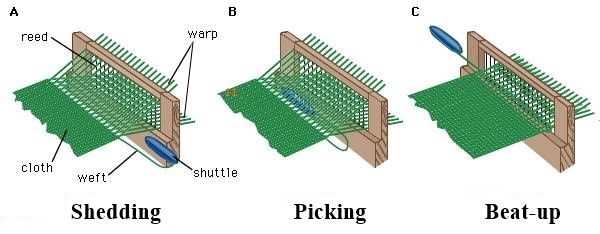

The weaving process consists of 3 basic / primary motions: Shedding, Picking & Beat-up.

Shedding: Separating the Warp yarns into 2 layers by lifting and lowering the shafts, to form a tunnel is called the Shed. See the Shedding in below mentioned figure A:

Picking: Passing the Weft yarn (Pick) across the Warp threads through the shed is called Picking. See the Picking in below mentioned figure B:

Beat-up: Pushing the newly inserted Weft yarn (Pick) into the already woven fabric (at fell of the cloth) using the Reed is called Beat-up. See the Beat-up in below mentioned figure C:

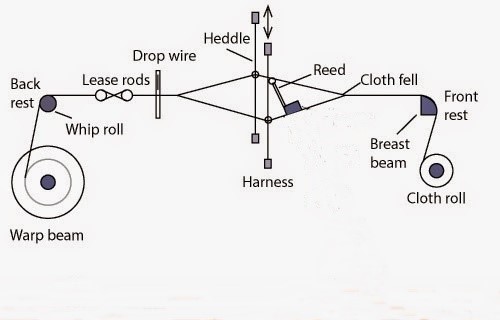

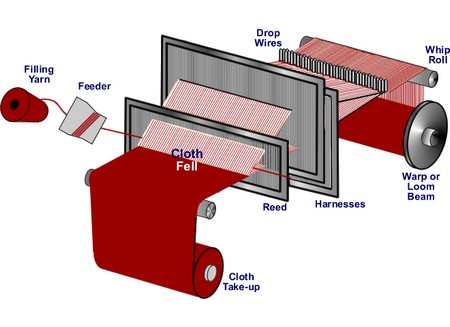

The weaving process consists of 2 secondary motions: Let-off & Take up.

Let-off: This motion delivers Warp yarns to the weaving area at the required rate and at a constant tension by unwinding it from a flanged tube known as the weaver’s beam or warp beam.

Take up: This motion draws the woven fabric from the weaving area at a constant rate (this rate is depending upon required PPI) then winds it onto a cloth roller.

Mainly 2 Auxiliary functions are required for the weaving: Warp Stop Motion & Weft Stop Motion.

Warp Stop Motion: This mechanism is responsible to stop the loom when a Warp yarn breaks or excessively loose.

Weft Stop Motion: This mechanism is responsible to stop the loom when a Weft yarn breaks or the Weft runs off the Weft Package.

A general sketch of threads and woven fabric’s flow on the loom is shown in the below figures:

Yarn Count is a numerical value, which express the diameter (Coarseness or Fineness) of the yarn and also indicates relationship between length and weight (the mass per unit length or the length per unit mass) of that yarn.

There are two types of Yarn Count Systems: Direct Count System & Indirect Count System.

Direct Count System: Here, the length is fixed. The weight per unit length is the Yarn Count. All Direct Count Systems are having fixed length of the yarn and weight of the yarn varies according to its diameter.

| Numbering System | Unit of Length (I) | Unit of Weight (W) |

| Tex (T) | 1000 meters | No. of Grams |

| Denier (D) | 9000 meters | No. of Grams |

| Deci Tex (dtex) | 10000 meters | No. of Grams |

| Jute Count | 14400 yards | No. of Pounds (lb) |

i.e., 40 Tex of filament yarn means 1000 meters of yarn weigh 40 grams.

Indirect Count System: Here, the weight is fixed. The length per unit weight is the Yarn Count.All Indirect Count Systems are having fixed weight of the yarn and length of the yarn (in form of Hanks / Coils) varies according to its diameter.

| Numbering System | Unit of Length (I) | Unit of Weight (W) |

| English Cotton Count (Ne) | 840 yards | 1 Pound (lb) |

| Metric Count (Nm) | 1000 meters | 1 kg |

| Woolen Count (YSW) | 256 yards | 1 Pound (lb) |

| Jute Count | 14400 yards | No. of Pounds |

Regular / Basic weaves give even and easily identified appearance to the woven fabric. Some of the commonly used regular weaves are as below:

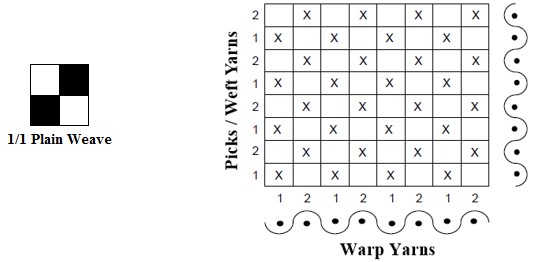

1/1 Plain: Plain weave is the most commonly used weave in the weaving industry.

The principle involved in the construction of plain cloth is the interlacement of any two continuous threads either warp or weft in an exactly contrary manner to each other, with every thread in each series passing alternately under and over consecutive threads of other series interlaces uniformly throughout the fabric. By this plan of interlacement, every thread in each series interlaces with every thread in the other series to the maximum extent, thereby producing a comparatively firm and strong texture of cloth.

Set of the Warp Yarns, skipping one warp yarn alternatively, making up and down movement one by one creates a shed and this is what being done in plain weave. It means 50 % of total Warp Yarns remains up and rest of 50 % of them remains down always.

A complete unit of the plain weave occupies only two ends of warp yarns and two picks of weft yarns.

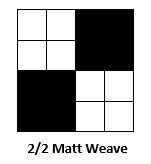

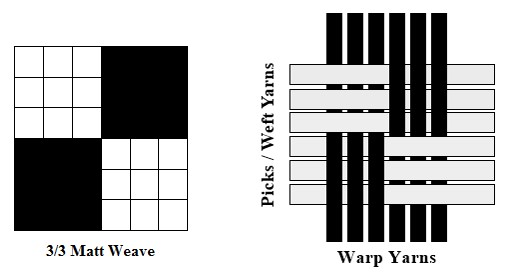

2/2 Matt: In case of regular matt weave, the plain weave is extended equally in the warp and weft directions in bunch of 2 or 3 or 4 warp and weft yarns.

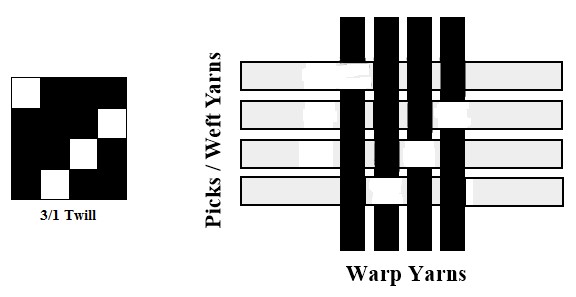

Twill Weave: Twill weave is done by passing the weft yarn under the 2 or more warp yarns and then over the one warp yarn and so on. Twill weave distinguishes from other weaves is because of the presence of visible diagonal lines that run across the width of the woven fabric.

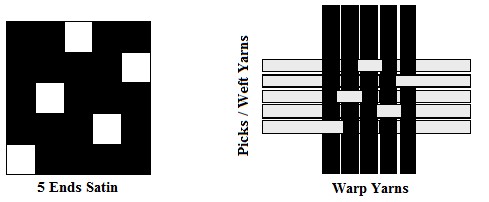

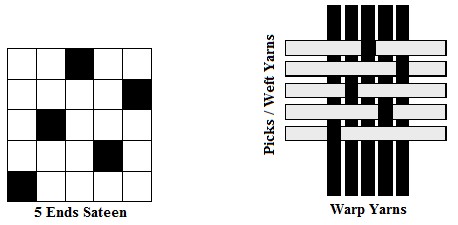

Satin and Sateen Weaves: Satin is the Warp faced rearranged twill and Sateen is the Weft faced rearranged twill. Thus satin is the reverse side of the Sateen weave. The highlighted feature of these weaves are their brightness / lustrous appearance and smoothness.

For weaving different kind of Regular / Basic weaves, loom / machine must be equipped with at least separate Cam Shedding mechanism with minimum 7 heald frames accommodation.

With above loom specifications, weavers can able to weave a fabric with basic weaves like 1/1 Plain Weave, 2/2 Matt Weave, 2/1 Twill Weave, 3/1 Twill Weave, 3/1 Broken Twill Weave, 1/3 Twill Weave, 1/3 Broken Twill Weave, 2/2 Twill Weave, 4/1 Twill Weave, 5 Ends Satin, 5 Ends Sateen, Combination of 1/1 & 2/2 Weave, Combination of 1/1 & 3/1 Weave, Combination of 2/1 & 1/1 Weave, Combination of 5 Ends Satin & 1/1, Combination of 5 Ends Satin & 2/2, Combination of 5 Ends Sateen & 1/1, Combination of 5 Ends Sateen & 2/2, etc.

- It is not possible to run different kinds of basic weaves with the help of Tappet Shedding similar to that of Shuttle loom.

Mainly there are two reasons clarifying this ‘NO’:

(1) Not possible to accommodate more than 4 heald frames with Shuttle loom type Tappet Shedding. Where as many of weaves and combination of weaves need 5 or 6 or 7 heald frames at least.

(2) This kind of traditional Tappet Shedding have fixed cam shedding mechanism, means there is fixed drive / fixed rotation ratio to Tappet motion from loom and hence not possible to run different kind of basic weaves.

For making fabric of many weaves and combination of weaves, one must have weaving machine equipped with separate cam shedding mechanism in which weavers can achieve different basic weaves by just replacing concerned cams.